23,400+ Miles of Microfilm: Crowley Scans Social Security Records

1.2 Million Reels of Microfilm Scanned in Less Than Two Years with Crowley Digitization Services

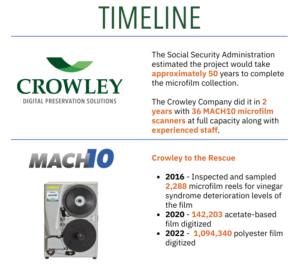

Over the past several years, The Crowley Company (Crowley) has been an effective partner with the Social Security Administration (SSA) on several massive inventory and digitizing projects that were successfully completed within budget and within record time thanks to the experience of Crowley’s Digitization Services team. In February 2017, Crowley worked on a massive microfilm inventory project to begin inspecting, creating an inventory and barcoding an archival collection located in an underground mine in Pennsylvania. This massive project lead to the microfilm collection assessment project, completed in September 2017, where Crowley’s team inventoried 1.2 million roll collections. After doing such an amazing job on both of these projects, Crowley was requested for a third time in 2020 to complete another important project that will allow Crowley to successfully assist the SSA in overcoming some challenges with their microfilm collections.

A Brief History of The Social Security Administration and Microfilm

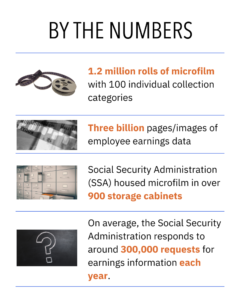

The SSA started using microfilm as their permanent storage media in 1938. The microfilm created included every U.S. worker’s earnings data and employer-reported wages from W-2 forms, W-3 forms, Master Earnings Files (MEF), annual earnings, quarterly earnings, wage adjustments….forms, forms and more forms! Eventually, the SSA record sets (referred to as ‘collections’) totaled over 100 individual collection categories and accounted for the equivalent of 1.2 million rolls of microfilm created from 1938 to 1980. The microfilm rolls contained well over three billion pages/images of employee earnings data.

Prior to digitization, the SSA data research staff used a combination of computer database search tools to identify the rolls of film that might contain the requested claim data. The SSA researcher pulled the roll(s) of film, returned to his/her desk location and would search through the film roll using a microfilm reader to identify the claimant’s name and to verify the earnings in question. The process was manual and time-consuming.

The SSA’s casework and workloads were highly dependent on the data stored on microfilm. Staff at both facilities were using the microfilm reels daily to find, confirm, adjust and determine workers and retirees’ earnings and their resulting Social Security benefits. During 2015, the SSA staff responded to around 300,000 requests for earnings information.

With the microfilm collections degrading rapidly due to vinegar syndrome, time was not on the side of the SSA records storage and access.

Should SSA Digitize?

In response to the workload demand and the decay of microfilm records, several digitization studies were performed by the SSA to examine the feasibility of digitizing their vast microfilm collections. Each of the studies were conducted to varying detail and each study had a central focus including an examination based on library usage. In 2008, as a result of the previous studies and proof of concept to determine feasibility, the SSA conducted a due diligence examination of the available high-speed microfilm scanner solutions. The SSA then selected the Mekel Technology MACH5* microfilm scan systems (later upgraded to MACH10 capabilities) designed and manufactured by Crowley. After acquiring six MACH-Series scanners between 2010 and 2011, the SSA began digitizing the “SS-5” (Social Security Number) microfilm collection by Social Security Number sequence. These early efforts resulted in the digitization of 84,695 microfilm reels containing 210 million stored images.

Next, the SSA began scanning the SS-5 film reels that were organized by Reference Number. The digitization of these 62,635 microfilm reels began in October of 2014. Based on the progress made during the digitization of the SS-5 collection and utilizing existing resources, the SSA estimated it would take approximately 50 years to complete the scanning of the remaining one million reels that represented the entire microfilm collection.

Examining the Challenges

Northrop Grumman, the primary IT contractor/consultant at the SSA, was tasked with examining the challenges of labor-intensive record searches, deteriorating films and the need to automate the records through electronic searching. To do so, they began a year-long examination of the SSA’s workflow processes at the SSA’s Maryland facility and at the Security Records Branch in Pennsylvania. The intensive study included a team of workflow analysts, productivity experts and microfilm subject matter experts.

Upon the study’s completion in December of 2015, Northrup Grumman issued a report, Microfilm Records Digitization Process Improvement Study, making several recommendations to the SSA. These included: the need for a further analysis of the microfilm condition; a full inventory of the microfilm collections; and an expedited program for the digitization of the microfilms. These digitized images had to populate the SSA’s customized digital access platform designed by John Wychock of the SSA’s Wilkes-Barre Data Operations Center.

The SSA Microfilm Records Digitization Process Improvement Study Report, which was authored by The Crowley Company’s Dave Westcott during his tenure with Northrop Grumman, also estimated that the SSA cost to manually process a search from the microfilm collections would cost $7.91 per manual search compared to an estimated search cost of $0.67 when searching from the digitized microfilm images.

Digging Deeper

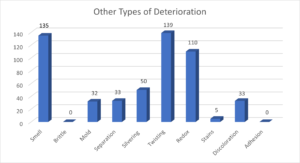

The Crowley Company joined the Northrop Grumman**/SSA microfilm study team in 2016 to perform an analysis of the microfilm deterioration conditions across a designated population of the films. Crowley team members inspected and sampled 2,288 reels of microfilm to create a valid statistical sample of the SSA film repository. The Crowley experts used Acid Detection (AD) strips supplied by the Image Permanence Institute / Massachusetts Institute of Technology (MIT) to collect the vinegar syndrome deterioration levels of the films. The AD strips were placed inside the film canisters and boxes, removed from the containers the following day and the results (acid content levels) were recorded in a database designed and provided by Crowley.

The database collection form designed by Crowley allowed the film inspection team to a) identify the source of the microfilm (i.e. the collection); b) identify the storage location along with the AD strip levels; and c) note any other deterioration conditions to include redox, silvering, deteriorating splices, film curling and twisting.

The resulting study demonstrated the deterioration levels of each sample and the data was compiled for analysis. The findings confirmed that the deterioration levels of the microfilm required immediate action to rescue the films from the potential loss of data.

Moving Forward with Digitization

Due to the vulnerability and instability of the microfilm, the SSA engaged Northrop Grumman and their partnership with Crowley to begin the digitization of all cellulose acetate-based film in the SSA’s collection. This film made up a significant portion of all the existing records. Due to the records showing signs of vinegar syndrome deterioration, the team estimated that the fragile microfilms would only be useable through the end of 2020. The goal set forth by the SSA was to complete the acetate-based film digitization by December 2020 and the polyester film digitization by 2023.

To complete the project in a timely manner, the SSA decided that using a contractor, such as Crowley with digitization experience was key to providing the expertise and scale of resources to meet the variable workloads.

The SSA Security Records Branch underground facility managed by SSA’s Rob Rinker was upgraded to provide the Crowley team with a dedicated scanning room which included an upgraded ventilation system and safety equipment to protect the staff members from any health issues related to the deteriorating films. The workspace was configured with dedicated scanning workstations, barcode readers, film rewind and splicing stations and thirty-six (36) Crowley Mekel Technology MACH10 microfilm scanners. These scan systems were powered by the Mekel Quantum software suite, customized for the SSA digitization project and connected to a large onsite server room where the scanned images were transferred every evening in preparation for the secondary transfer to the SSA/Wilkes-Barre host computer platform.

The onsite Crowley team of capture experts, known in-house as “Crowley Boyers,” was managed by Larry DeMarchi and Deb Watkins under the leadership of Crowley’s Digitization Services director of operations, Patrick Hill, and project manager, Elizabeth Groombridge, both operating from Crowley headquarters located in Frederick, Maryland and making regular visits to the Boyers facility. As a retired SSA employee very familiar with the organization’s microfilm collections, Larry was a key component in reducing any learning curve between the SSA and The Crowley Company’s scanning activities.

Productivity and Progress

Logistically, the microfilm reels and canisters containing multiple reels were retrieved by the SSA staff and delivered to the Crowley scanning room. Film lengths varied between 10 to 1000 feet in length and required the team to balance the workflow processes and the number of scanners per operator from one to four scanners depending on the film roll length. The principal goal always was to keep all 36 MACH10 scanners operating at full capacity.

Workflow and metrics were measured and managed in real-time using an SSA-designed workflow measurement software and reporting tool. The workflow tool provided visibility to:

- scanning operator productivity

- machine uptime

- the number of minutes required to scan each roll

- the linear foot length of each roll

- the total work hours utilized by each scan station

- the estimated completion times and progress status for each microfilm collection

Working together with the SSA staff and refining the processes as the scan technicians became more familiar with the microfilm collections, the Crowley team completed the digitization of the deteriorating acetate films four months ahead of schedule, delivering the last images in August 2020 versus the projected December. Similarly, the Crowley team completed the polyester-based film collections on May 27, 2022, 16 months earlier than projected.

The total linear feet of microfilm scanned by the Crowley team was 123.6 million feet, just shy of enough microfilm to circle the Earth.

Mission Accomplished

The digitization process has helped to modernize the benefit determination and claims processes at the SSA by moving away from the analog and manual process of retrieving microfilm rolls to search for data. The SSA Claims Research staff are now able to retrieve the data from digitized images stored on the SSA’s image server at a more efficient pace and at a much lower cost per search. Additionally, these electronic images will better support portable workloads and teleworking by the SSA staff.

The digitization of the SSA microfilm collection has contributed to the SSA’s mission to preserve data for every U.S. worker’s earnings by scanning their microfilm records before they deteriorated.

*The MACH-series is manufactured by Crowley and the MACH5 has been discontinued.

**The Northrop Grumman IT Solutions contract division was acquired by Peraton effective October 1, 2021. Peraton was the prime contractor with The Crowley Company as a team member subcontractor from October 2021 through the completion of the SSA microfilm digitization project.

About the Author

About The Crowley Company

The Crowley Company is a full-solution imaging partner. From micrographics equipment and microfilm to desktop, production and patron scanners to conversion services, The Crowley Company has aided records managers, archivists, librarians, researchers, students and others throughout the world with archival preservation, records management and digitization solutions for nearly forty years.